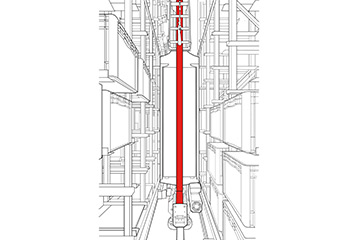

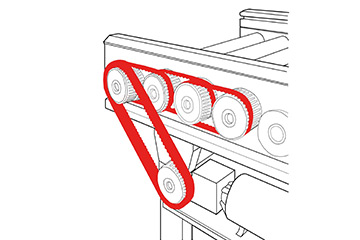

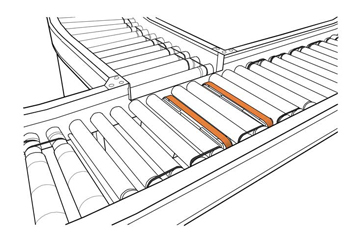

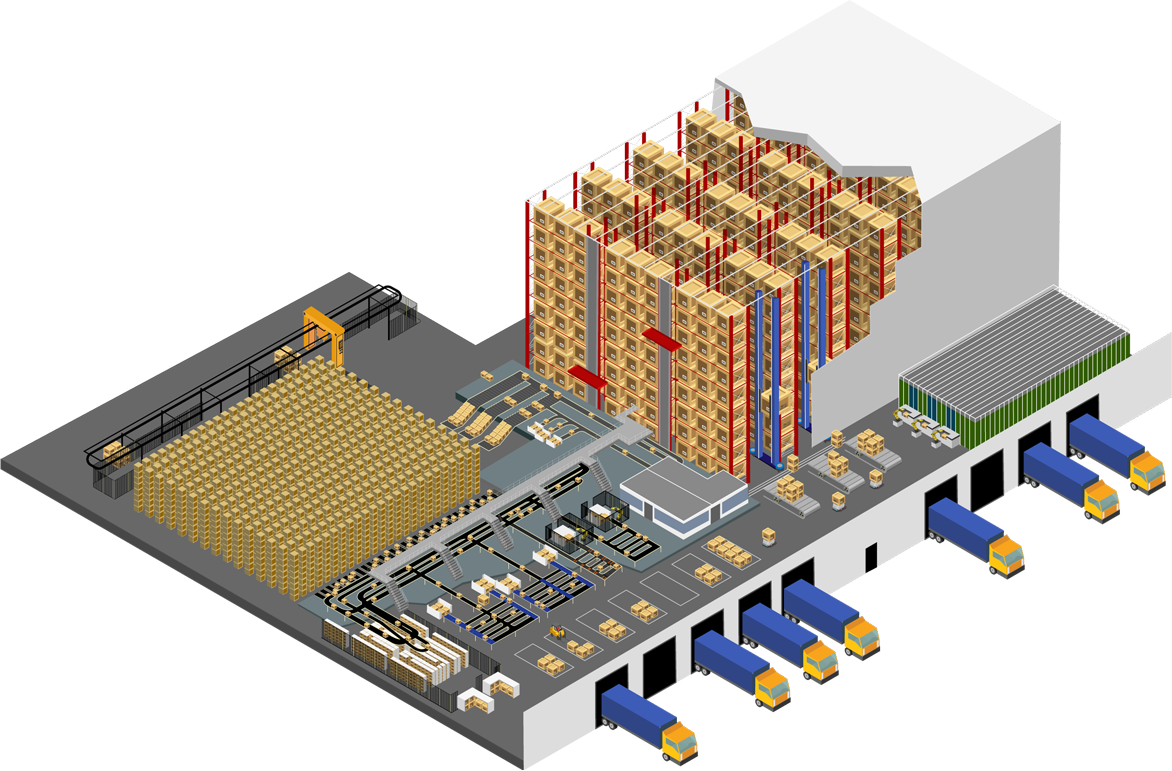

Megadyne’s expertise in elevator and lift solutions extends to industrial elevators. Our belting solutions are used in vertical and bi-directional elevator applications.

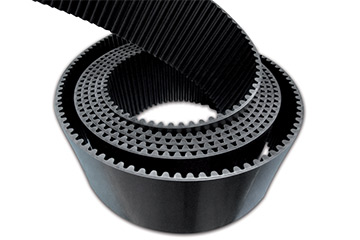

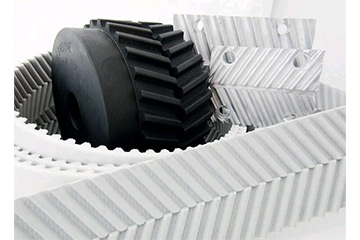

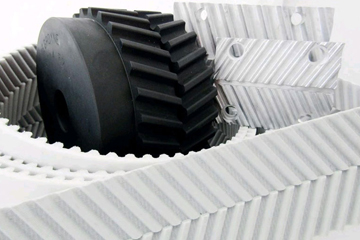

Our vast portfolio of Megalinear open end urethane timing belts and RPP Steel open end rubber timing belts are designed to handle the rigors of these lift applications.

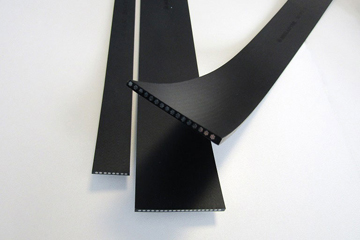

Megalinear P3.3 is an open end Traction Belt specifically designed for use in lifting industries.

Megalinear GW was designed with tooth stiffness and special high tension zinc coated steel cords for high load lift applications guaranteeing high transmittable power under continuous substantial loads.

Megalinear QST has an advanced offset tooth design with an NFT cover that is self-tracking and provides a precise and continuous mesh between belt and pulley resulting in reduced noise level.

Learn More